AP SERIES: TALL-RISE LIFTS

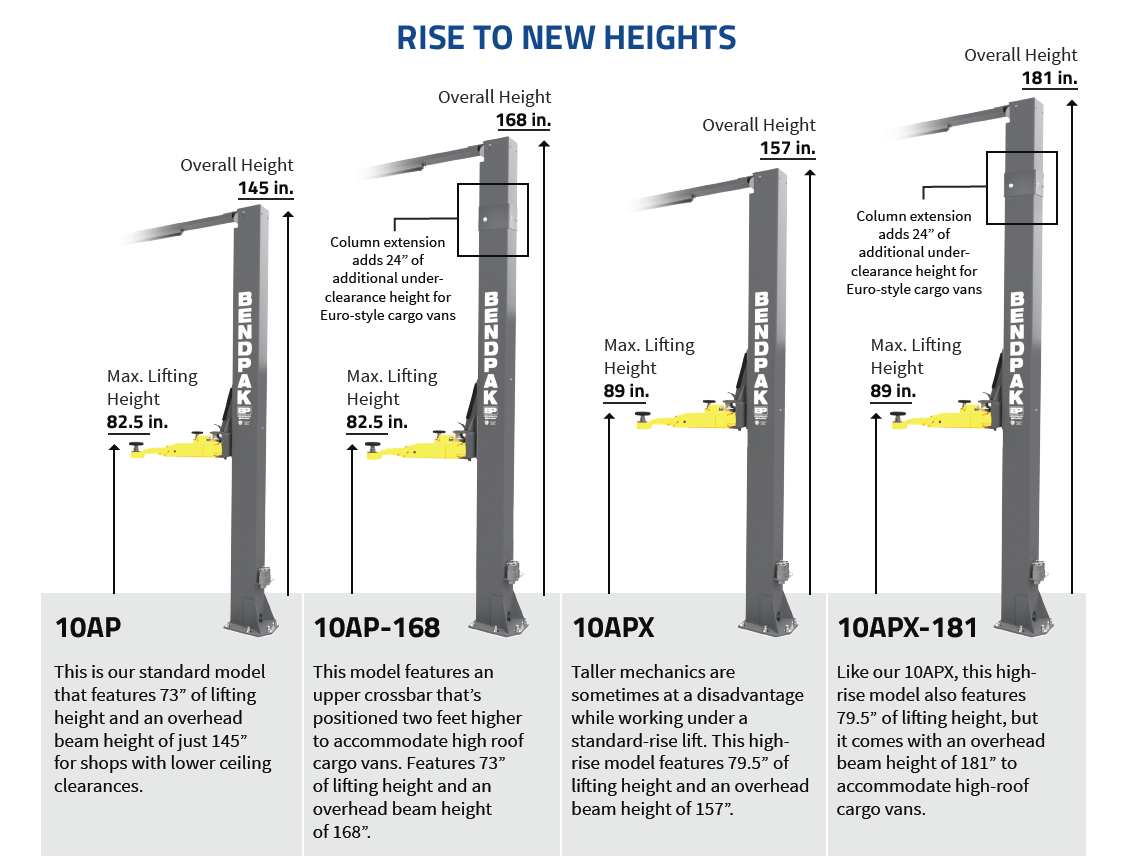

BendPak’s 10APX has been designed for mechanics who often find themselves working in uncomfortable positions. With a lifting height of 79.5″ and an overhead beam of 157″, this robust lift provides ample room for comfortable and efficient work. For those handling larger vehicles, the 10APX-181 is the perfect solution. It maintains the same lifting height but boasts an overhead beam height of 181″, making it ideal for high-roof cargo vans. As part of BendPak’s AP Series, this lift offers all your favorite features, including a 10,000-lb. lifting capacity, Low-Pro arms, Bi-Metric™ arms, and more!

A NEW PARADIGM IN LIFTING

Auto repair shops working on the latest technology need the most advanced tools to keep up with the incoming wave of new vehicles. The AP Series of two-post lifts feature a revolutionary design that incorporates the best qualities of today’s lift types into a new concept in car lift engineering. The result is a lift unlike any other on the market, purposefully designed for extreme use, high loads, and operator safety and efficiency.

BI-METRIC™ SWING-ARMS

The AP Series offers the convenience of wide or narrow installation options in one configurable package. These durable, safe, and reliable lifts feature advanced Bi-Metric™ arms capable of both symmetric and asymmetric lifting. The simple yet sophisticated design minimizes service and maintenance costs, reducing operating expenses and boosting productivity.

NEW TECHNOLOGY FOR INCREASED OPERATOR SAFETY

The automotive industry is well known for continuously being highly receptive to emerging technologies. Innovations have already transformed how cars use fuel, with electric and hybrid systems starting to replace internal combustion engines as the future’s driving force. Forecasters predict that EVs will make up a significant percentage of all vehicles produced and sold, and these EVs are considerably heavier than traditional gasoline or diesel-powered vehicles. This added weight has crucial implications for mechanic safety when vehicles are lifted for service. The extra pounds introduce significantly more stress and force on automotive lift components, especially when considering two-post lifts.

ELECTRIC VEHICLES ARE GETTING LARGER AND HEAVIER. ARE YOU READY?

The AP Series design is influenced by the fact that EVs are typically heavier than your standard commuters. With its intuitive design, the 10APX allows technicians to service EVs, trucks, vans, and sports cars more efficiently than ever before. BendPak engineers have focused on providing greater under-car access with extremely low-profile arms and extra-wide column spacing. By using high tensile-strength steels for all critical load-holding components, they’ve designed swing arms with greater telescoping movement and tube profiles better suited for low ground clearance vehicles and outer-positioned EV lifting points. Safety-critical design enhancements are integrated throughout.

Electric vehicles require newer lifts to safely accommodate their increased weight due to added batteries, reinforced frameworks, suspension, and protective metal armor. The 10AP is the perfect EV service solution, featuring reinforced construction and purposefully engineered design elements. Each 10AP model offers improved under-car access, increased arm travel, and minimal arm retraction for versatile lift support positioning, making it ideally suited for electric vehicle service.

AUTOMATIC ARM RESTRAINT SYSTEM PREVENTS UNPLANNED MOVEMENT

Swing arm restraints have long been used on two-post lifts to minimize arm shifting during vehicle loading and service. However, traditional systems often struggled withstanding the excessive forces when vehicles unexpectedly shifted on the support pads or adapters of the swing arms, typically due to improper loading or sudden changes in the center of balance when heavy drivetrain components are added or removed.

The AP Series is equipped with BendPak’s patented Automatic Swing Arm Restraint System (ASARS). This system is designed to handle the elevated forces encountered during heavy vehicle service. The heavily forged-steel design of this patented arm restraint system provides a full 360-degrees of grip, securing the lift arms firmly in place with over 2000 pounds of load-holding force. This prevents unplanned swing-arm movement during lift use and vehicle service operations.

ASARS is an adaptive system that requires minimal operator involvement and delivers unparalleled holding power. Its distinctive power-hold design ensures precise, non-shifting action, while a quick-release lever allows for the instant release of clamping pressure. This innovative feature makes the AP Series a leader in safety and efficiency for automotive lifts.

TRIPLE-TELESCOPING NESTED SWING ARM DESIGN

The revolutionary and patented swing arms are designed to accommodate various vehicle lifting points. Unlike traditional two-post lift arms, the 10APX arms offer a shorter retraction and greater extension, providing operators with numerous positioning options – offering the best of all worlds.

The inner sliding arm moves freely without being obstructed by arm end plates, tube closeouts, or the arm pivot pin. The inner tubes fully retract through the back of the arm assembly and even beyond the arm pin, allowing for exceptional retraction and extension.

LOW PROFILE ARMS

BendPak’s exclusive Low-Pro™ swing arms feature telescoping channels designed with a shorter profile and a dropped-end pad receiver, making them ideal for servicing vehicles with lowered chassis heights. They provide enhanced access to difficult-to-reach lift points, offering increased versatility while minimizing the potential for damaging vehicle side skirts, running boards, or ground effects.

SCREW PADS AND ADAPTERS THAT ADJUST TO YOUR NEEDS

The double-telescoping screw adapters feature durable polyurethane pads resistant to gouging and tearing, offering adjustable height for level lifting under various conditions. This design ensures precise frame engagement, prioritizing technician safety during vehicle servicing.

Optional stackable adapters further enhance vertical pad placement, providing precise and secure support for vehicles. The adapters’ drop-in design allows for quick and effortless use, while a column-mounted rack keeps them neatly organized and secure, optimizing workshop efficiency.

INNOVATIVE SAFETY LOCK SYSTEM

The patented automatic safety lock system enhances operator efficiency and safety significantly. Its innovative design ensures automatic engagement of safety locks during lift rising operations, while an ergonomic single-point release enables operators to effortlessly disengage the safety locks during lift descent with a simple push of a finger. It’s as easy as that.

Features

- Durable powder coat finish

- Expandable top beam accommodates wide or narrow drive-thru configurations

- Double-telescoping screw pads offer increased versatility

- Padded overhead safety shutoff bar

- Exclusive Bi-Metric™ arm design for more versatile arm positioning

- Single-point safety release

- Drop-end arms provide a lower pad height

- Dual hydraulic direct-drive cylinders

- Oversized 53″ & 59″ tall carriages for superior strength and durability

- Electric / hydraulic HVLP power system

- Self-lubricating dura-glide UHMW polyethylene bearing system

- Safety locks in each column spaced every 3″

- Automatic arm restraints withstand over 2000-pounds of side force

- 3/8″ (10mm) High-strength multi-strand galvanized steel equalizing cable

- Oversized cable sheave diameter reduces cable fatigue

- Four triple-telescoping arms

- ALI certified

Specs

- Lifting capacity: 10,000 lbs. / 4,536 kg

- Max. Capacity: 5,000 / 2,268 kg (Rear Axle)

- A – Max. Rise: 75.5 in. / 1,918 mm

- B – Lifting Height: 79.5 in. / 2,019 mm

- C – Max. Lifting Height: 89 in. / 2,261 mm

- D – Min. Height: 4 in. / 102 mm

- E – Overall Height: 157 in. / 3,988 mm

- F – Overall Width: 145 in. / 3,683 mm (Wide)

- G – Outside Columns: 137.5 in. / 3,492 mm (Wide)

- H – Inside Posts: 118.5 in. / 3,010 mm (Wide)

- I – Drive-Thru: 107.5 in. / 2,730 mm (Wide)

- J – Floor to Top Switch: 152 in. / 3,861 mm

- K – Front Arm Reach: 50 in. / 1,270 mm (max)

- L – Rear Arm Reach: 59.25 in. / 1,504 mm (max)

- Max. load per Lift Arm: 2,500 lbs. / 1,134 kg

- Screw Pad Adjustment: 2 in. / 51 mm

- Time to Full Rise: ≈ 45 seconds

- Motor: 220 VAC, 60 Hz, 1 Phase

- Sound: <70 dB