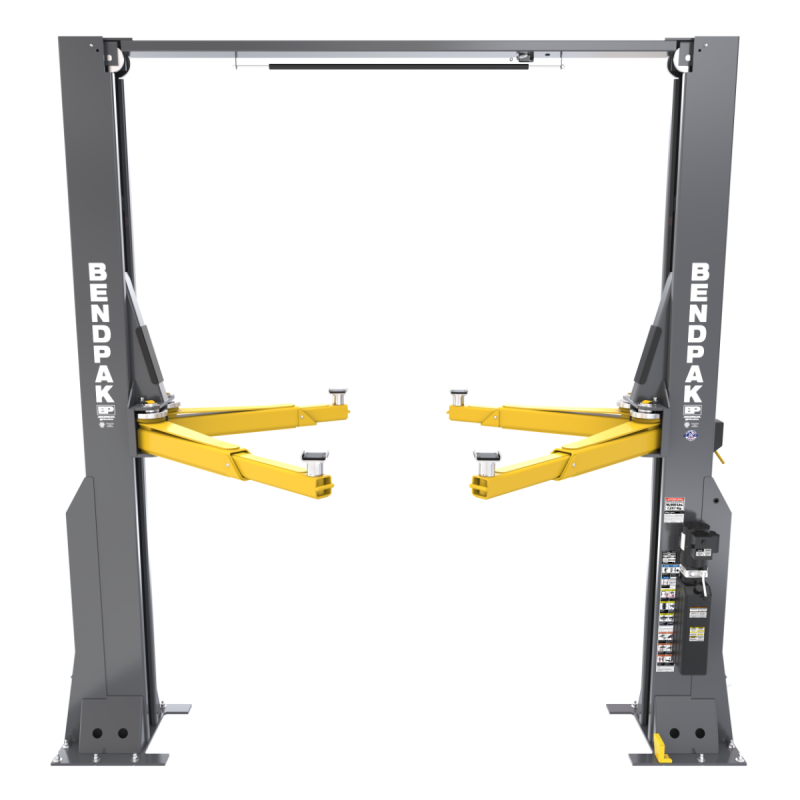

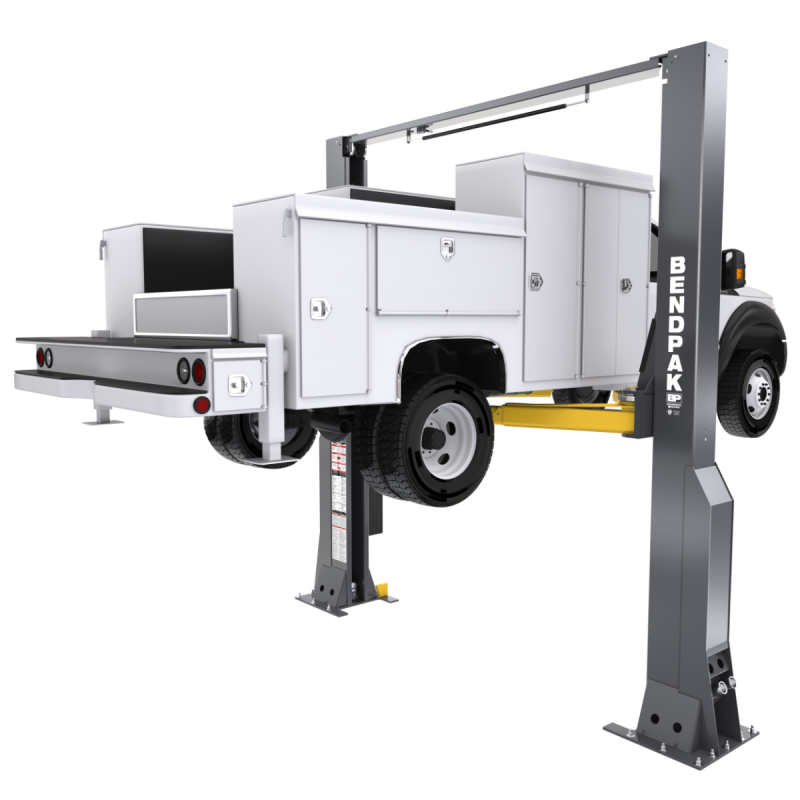

BendPak’s 16AP Series, renowned for its heavy-duty fleet service, airport maintenance, and emergency vehicle management capabilities, stands out with its impressive 16,000-pound lifting capacity. Equipped with long-reaching telescoping arms and a diverse array of lifting adapters, this Super-Duty AP Series seamlessly accommodates virtually every chassis configuration, making it an invaluable addition to any fleet operation.

The 16AP Series offers oversize dimensions and enhanced capabilities that surpass traditional two-post lifts. These lifts can handle more weight, reach higher, extend farther, and provide unmatched vehicle-supporting stability. Featuring fewer moving parts, they are less prone to wear and tear, easier to maintain, and more cost-effective to operate, translating to significant cost savings. Increased uptime ensures more efficiency and free time.

Designed to safely accommodate large commercial trucks and effortlessly lift long, awkward vehicles, the Super-Duty AP Series excels in handling heavy fleet tasks. Key features include generously spaced columns for easier entry and exit and rugged, far-reaching arms that enhance lifting point coverage for greater stability. Ergonomic operator controls ensure simple and safe operation, boosting productivity and profitability.

Setting New Standards with ASARS

BendPak’s patented Automatic Swing Arm Restraint System revolutionizes safety by eliminating unplanned movement. With over 2000 pounds of load-holding force and a full 360-degree grip, ASARS ensures secure arm positioning during vehicle service. Its quick-release lever further enhances operation, providing unmatched stability and control.

Enhanced Accessibility with Low-Pro™ Swing Arms

Navigate low-profile vehicles effortlessly with BendPak’s exclusive Low-Pro swing arms. Featuring telescoping channels and dropped-end pad receivers, these arms provide improved access to hard-to-reach lift points while minimizing the risk of damage. Combined with stackable adapters and two-stagespin-up screw pads, they deliver precise and safe vehicle support for any task.

Revolutionary and patented swing arms are specifically tailored for varying vehicle lifting points. Unlike traditional two-post lift arms, AP arms retract shorter and extend farther; offering lift operators a myriad of lift arm positioning options ― it’s like having the best of all worlds.

The Future is Triple-Telescoping

The innovative three-stage arms achieve more telescoping movement due to their patented nesting feature that results in greater retraction and farther reach. Inner sliding arm movement is no longer impeded by arm end plates, tube closeouts, or even the arm pivot pin itself. The inner tubes retract fully through the back of the arm assembly end even beyond the arm pin, resulting in more achievable retraction and extension.

Industry-Leading Safety Features

Experience peace of mind with BendPak’s automatic safety lock system, engaging seamlessly during lift rising operations and offering a single-point release for effortless descent. Prioritize safety with BendPak’s commitment to industry-leading safety features, ensuring a streamlined workflow and optimal protection for both operators and vehicles.

Unmatched Versatility with Bi-Metric™ Swing Arms

BendPak’s exclusive Bi-Metric swing arms offer unparalleled flexibility, allowing for customized lift configurations without the need for arm switching. Whether loading vehicles symmetrically or asymmetrically, this 2-in-1 design streamlines vehicle servicing, making it faster and safer than ever before with the 16AP in your shop.

Features

- Durable powder coat finish

- Expandable top beam accommodates wide or narrow drive-thru configurations

- Double-telescoping screw pads offer increased versatility

- Padded overhead safety shutoff bar

- Exclusive Bi-Metric™ arm design for more versatile arm positioning

- Single-point safety release

- Drop-end arms provide a lower pad height

- Dual hydraulic direct-drive cylinders

- Electric / hydraulic HVLP power system

- Self-lubricating dura-glide UHMW polyethylene bearing system

- Automatic arm restraints withstand over 2000-pounds of side force

- Oversized cable sheave diameter reduces cable fatigue

Specs

| Max. Lifting capacity | 16,000 lbs. / 7,257 kg |

|---|---|

| A – Underlock Clearance | 76 in. / 1,930 mm |

| B1 – Max. Lifting Height (Top Lock) | 82.25 in. / 2,089 mm |

| B2 – Max Rise | 82.75 in. / 2,102 mm |

| C – Max. Lifting Height w/ Adapters |

89.75 in. / 2,280 mm |

| D – Min. Height w/ Pad | 7.75 in. / 195 mm |

| E – Overall Height | 169 in. / 4,294 mm |

| F – Overall Width | 168 in. / 4,267 mm |

| G – Width, Outside Posts | 149 in. / 3,785 mm |

| H – Width, Inside Posts | 126 in. / 3,199 mm |

| I – Width, Drive-Thru | 107.75 in. / 2,740 mm |

| J – Floor to Top Switch | 163 in. / 4,128 mm |

| K – Lift Arm Reach | 36 in. / 931 mm (min) 65 in. / 1,651 mm (max) |

| L – Base Plate Width | 28 in. / 710 mm |

| M – Post to Base Plate | 9.5 in. / 241 mm |

| Max. load per Lift Arm | 4,000 lbs. / 2,268 kg |

| Motor | 220 VAC, 60 Hz, 1 Phase |

| Sound | <70 dB |

1) Lifting Height w/Pad is maximum lifting height with Pads adjusted to the lowest setting and no adapter(s). Maximum Lifting Height is maximum lifting height with Pads adjusted to high setting and with both tall and medium Adapters installed. 2) Special voltages available upon request. 3) Lift Arms measured from the pivot center to the end of the Lift Arm. Specifications subject to change without notice.